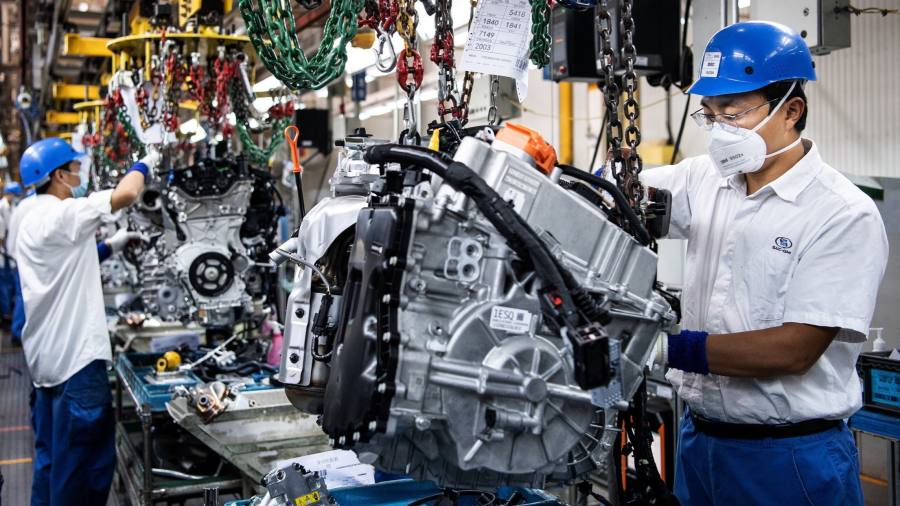

Carmakers quietly slice ties with China in provide chain shake-up

About the past 20 yrs, China has risen from obscurity to grow to be a worldwide chief in the car pieces marketplace.

Its growth was fuelled by European and American carmakers that farmed out the output of an rising amount of their components to China to preserve expenses and build links with the world’s largest automobile industry.

But worldwide teams have now released a quiet nonetheless concerted work to minimize their reliance on China’s sprawling network of parts makers, in accordance to sector executives and source chain specialists.

“There is a large-scale rethinking of logistics operations [across the industry],” stated Ted Cannis, a senior govt at Ford. “The source chain is going to be the emphasis of this decade.”

The transfer has been prompted by two developments. The very first is uncertainty brought on by China’s zero Covid-19 plan that forces vegetation to shut at quick observe.

“The longer the pandemic stretches, the a lot more uncertainty there is,” Volvo Vehicle boss Jim Rowan explained earlier this calendar year, when announcing the Geely-backed carmaker was expanding its use of non-Chinese parts.

But the 2nd is a for a longer period-term concern about a greater political decoupling in the function of a breakdown in China’s relations with the international local community, comparable to Russia, that could threaten trade.

Even though most global teams are unlikely to abandon the Chinese current market totally due to the fact of its measurement, they anticipate the flow of elements from the place to vegetation across the earth to drop in excess of time.

Therefore, foreign suppliers goal to make pieces and vehicles inside China completely for use inside of the country.

This cuts their reliance on Chinese factories for merchandise offered overseas, when retaining a secure regional offer chain for their very own vegetation within the country.

A quarter of China’s exported car or truck pieces stop up in US plants at existing, stated a report from Sheffield Hallam College in December, which highlighted the country’s increase as a world supplier above the previous two a long time.

In non-public, car bosses attract parallels with their expertise in Russia soon after president Vladimir Putin’s invasion of Ukraine.

Then, teams from Renault to Mercedes-Benz were forced to wind down or sell plants in Russia, even though significant components, this kind of as palladium, had to be sourced somewhere else.

“I imagine that the [auto] globe bought astonished by Russia and Ukraine,” reported Cannis. “The US-China romantic relationship is additional tricky than it has been previously . . . it’s a new planet.”

Nevertheless, the provide chain shake-up will just take time as carmakers hardly ever switch the sourcing of components until the end of a vehicle’s lifetime, which is about seven several years.

It could also show high priced for an field that already operates on lean margins.

“I never think the sourcing is the trouble. It’s the value that winds up altering,” claimed Tom Narayan, an automotive analyst at RBC.

“If anyone tries to change to the exact European or US providers, you’re restricting the offer, and the price tag will go up.”

Ted Mabley, provide chain expert at PolarixPartner, stated relocating away from China “will be searching at a price tag carry for both labour and material”.

This indicates carmakers ought to make savings somewhere else, notably with costs mounting in the change to electric powered, or danger getting uncompetitive.

“If we do not correct the affordability problem, the center courses will not obtain EVs [electric vehicles],” said Stellantis main executive Carlos Tavares.

“If 85 for each cent of the total value of a car or truck is pieces, if you never act on that 85 per cent, you will have no effect,” he mentioned, and that “requires us to use low charge countries”.

China is “not the only a single and not even the best”, he extra, with “plenty of options” throughout India, Mexico, and elements of north Africa and Asia.

Nevertheless, carmakers are also aiming to be additional arduous over their choice of suppliers as they emphasis on the resilience of the provide chain, as perfectly as expenses, to make guaranteed it does not break down.

“It is no for a longer time an period the place value is the big driving factor,” explained Masahiro Moro, senior managing govt officer at Mazda. “Right now, robustness of our provide chain also requirements to be viewed as to be certain the steady procurement of sections.”

Mazda stated it was shifting output of some parts manufactured in China to its property market in Japan.

This is a indication that even Japanese carmakers, which have a tendency to be significantly less dependent on the place than their rivals in Europe or the US, have began to reduce their reliance on China-based mostly supply chains.

The firm has by now asked extra than 200 of its suppliers that use factors manufactured in China to inventory up on inventories in situation there are disruptions in advance.

Yet regardless of increasing wariness driving boardroom doors, the business stays reliant on product sales to buyers in the Chinese marketplace, generating it hard for executives to talk overtly about some of the adjustments.

Executives reported Mazda’s reallocation was driven generally by issues more than the trustworthiness of materials as a result of the Covid lockdowns.

Japan-primarily based Honda admitted it was thinking of strategies to slice supply chain challenges, even though it denied media reviews that it was exploring the risk of making autos and bikes with as couple of China-manufactured sections as attainable.

“With a collection of manufacturing offer impacts thanks to several factors, such as the Shanghai lockdown, we are considering various techniques to hedge offer chain threats. Having said that, we are not precisely contemplating a circumstance of decoupling in China,” the company claimed.

Both equally Ford and Typical Motors have been proactively shifting parts out of the place for their US factories for a lot more than a year, in accordance to many persons.

GM stated: “Most of the elements we use in North The usa are previously sourced in North The usa, and source chain difficulties about the past couple of decades have strengthened the price of the resilience of our sourcing.”

The firm added that “most of our sourcing in China is for output in China”, and “we approach to continue on this approach”.

Supply chain challenges are better for the German carmakers Mercedes, BMW and particularly Volkswagen.

The 3 are so deeply embedded in China that, alongside German substances group BASF, they accounted for a 3rd of all European immediate financial investment concerning 2018 and 2021.

“The Germans are so tethered to China, not only for sourcing but on the shopper side too,” explained RBC’s Narayan. “That is basically right now the greatest risk that investors are hunting at.”

Having said that, Jörg Burzer, head of offer chains at Mercedes-Benz, pressured any variations to the company’s sourcing of pieces were being not driven by political issues.

It is “not about China or the US”, but “about the most effective established-up of the provide chain and the operations”, he advised the Financial Periods Worldwide Boardroom summit in December.

“Obviously, we seem at the resources which are close by, which could also be from European suppliers or US suppliers or Mexican suppliers,” he additional, stressing it was not about the nationality of a supplier.

More reporting by Claire Bushey in Chicago